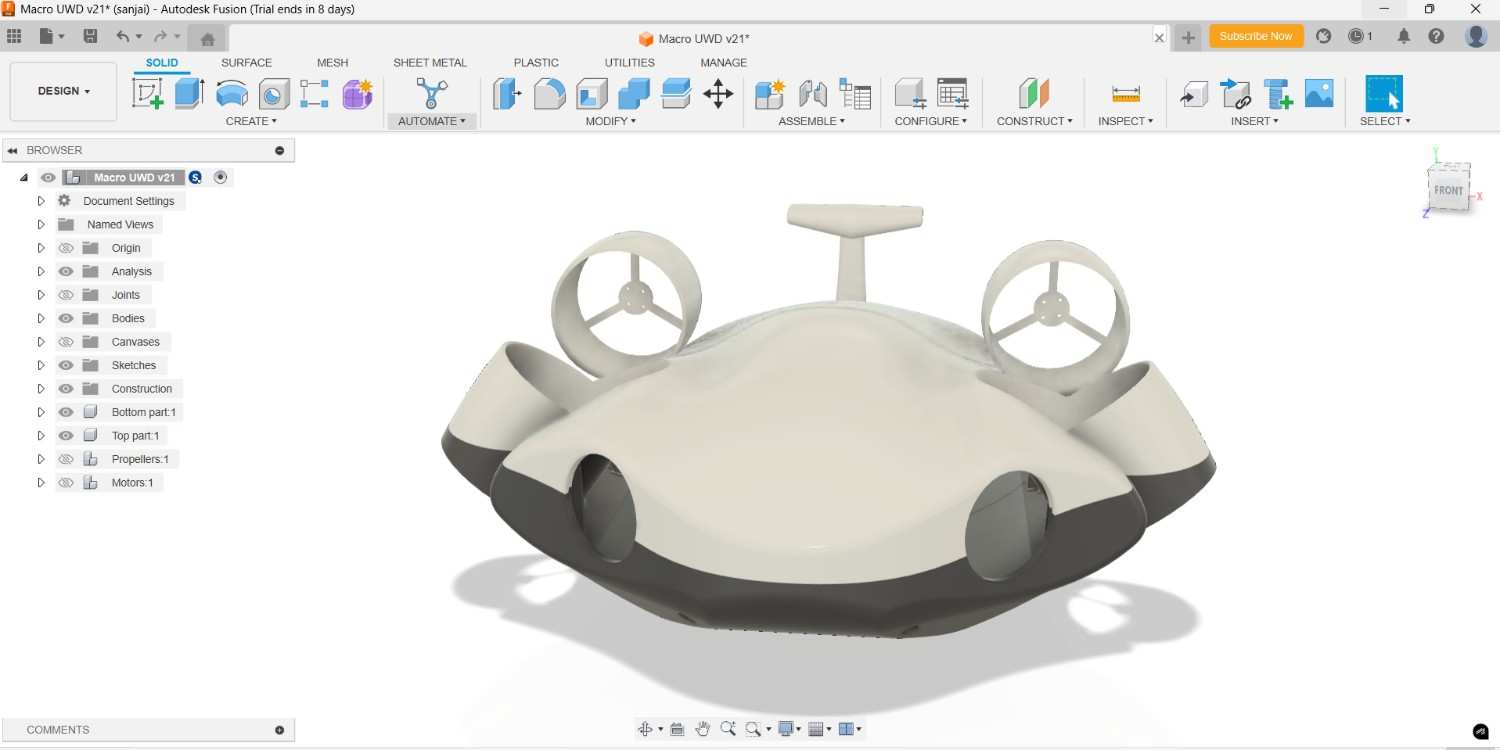

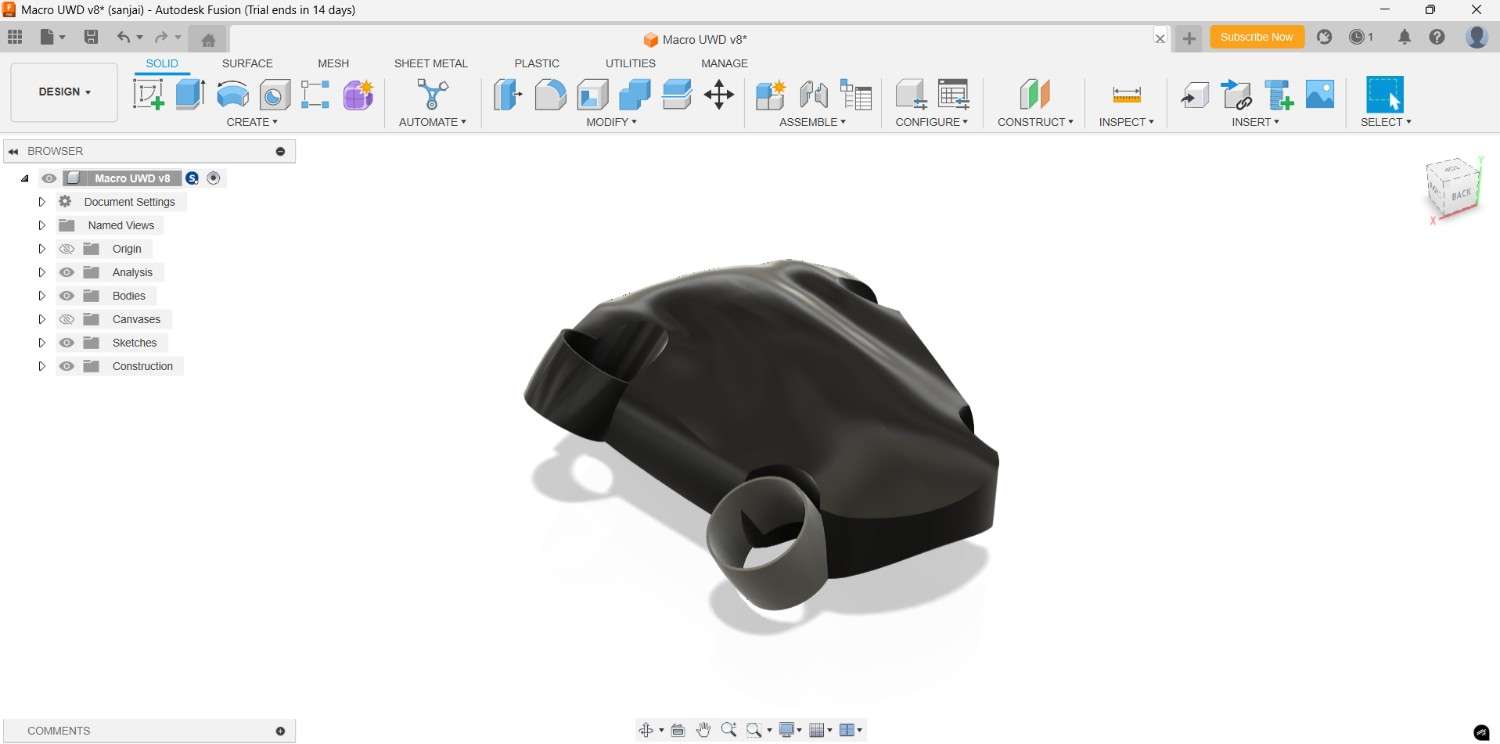

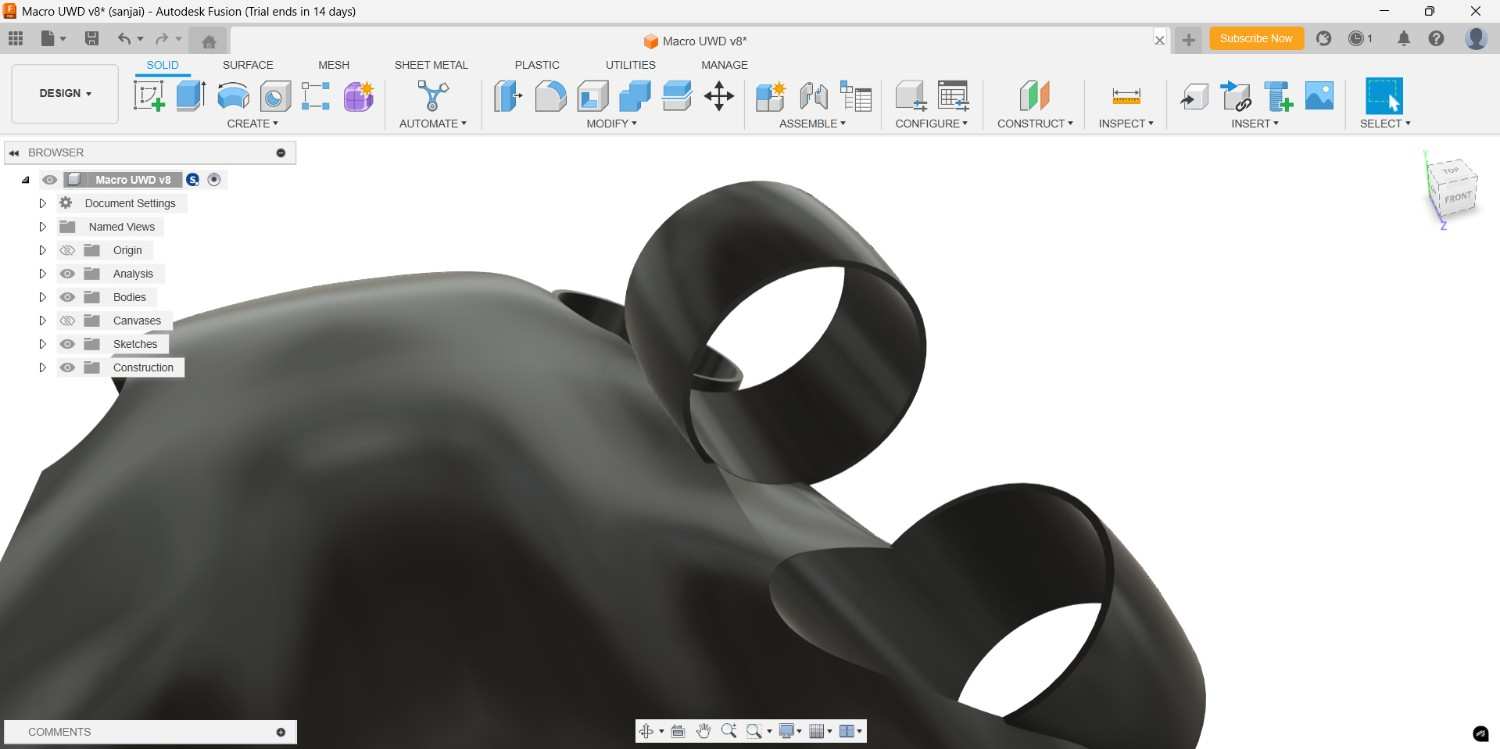

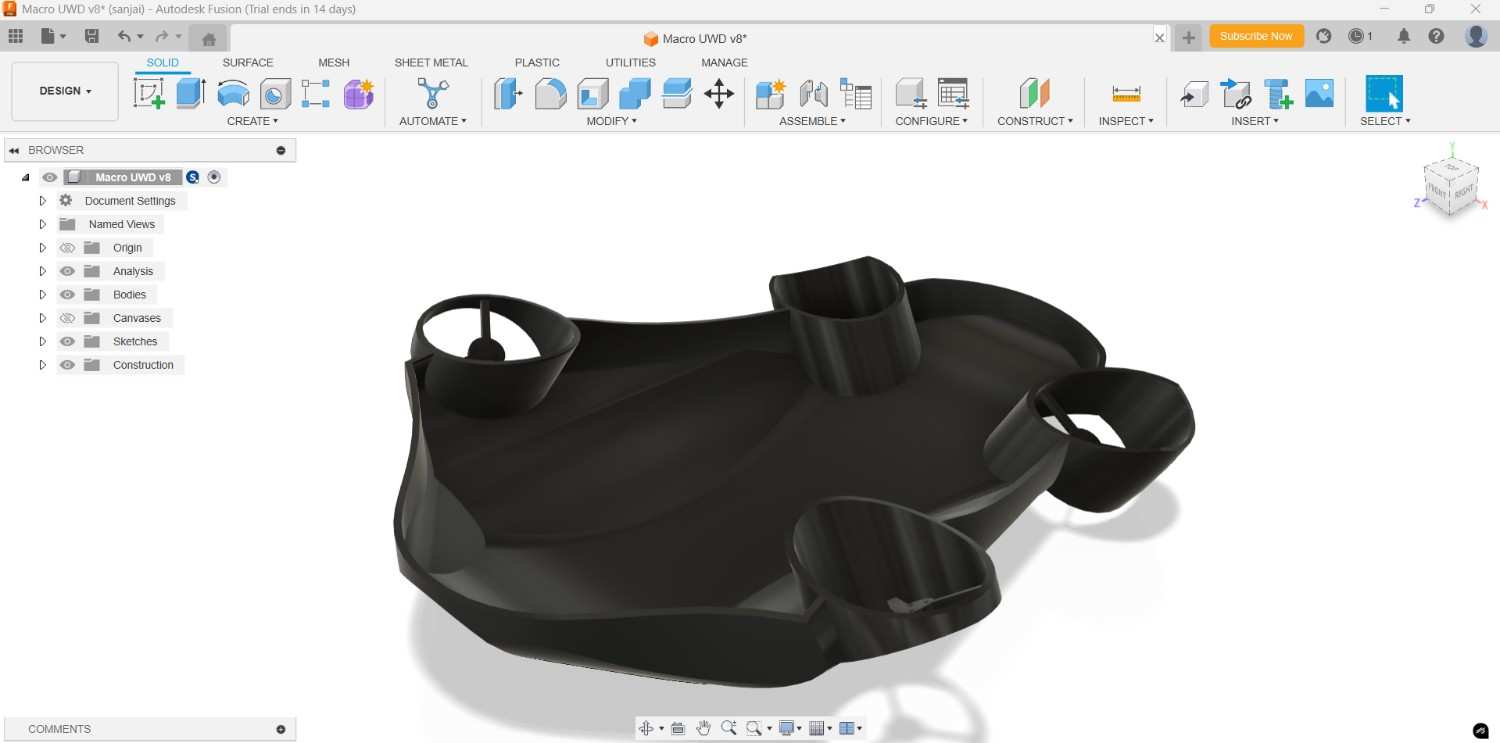

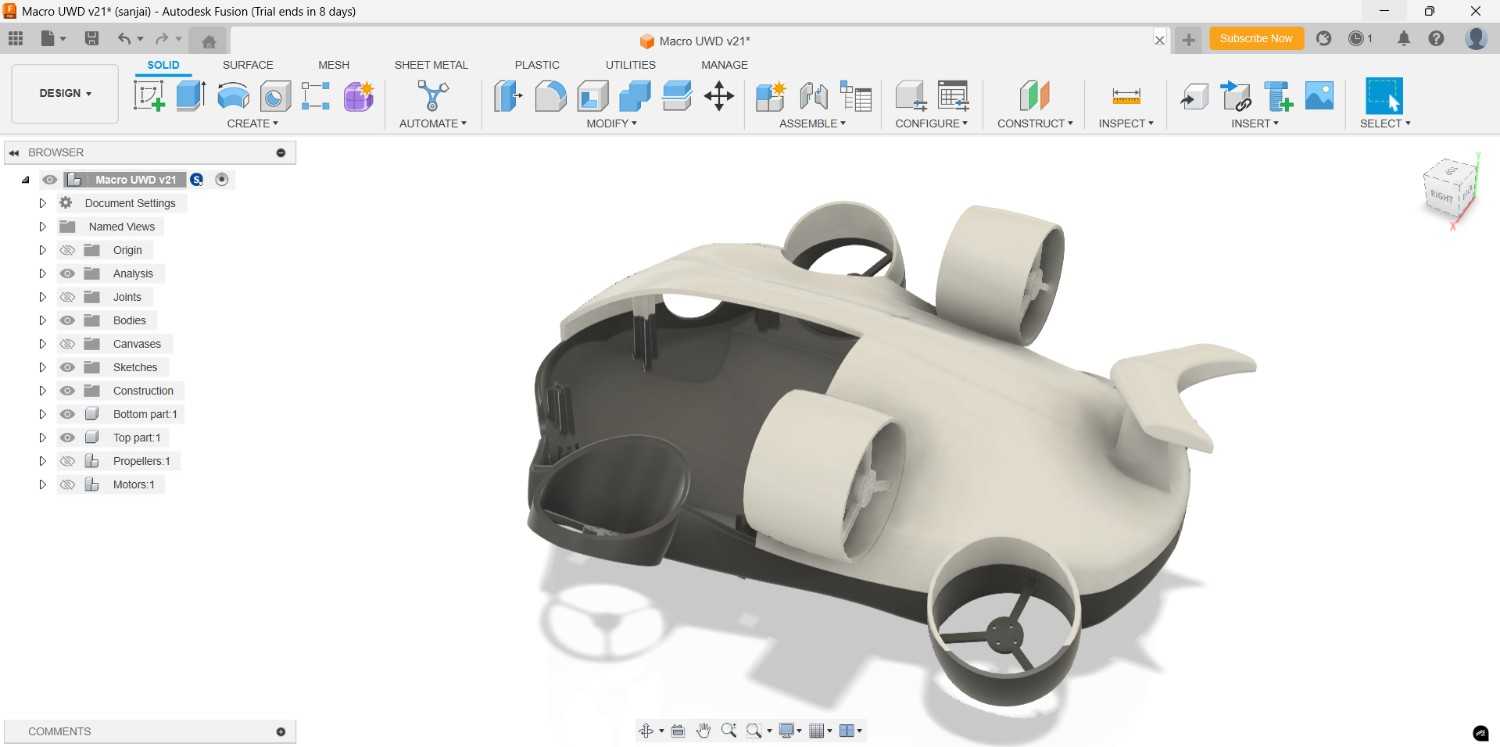

Final 3D Design

Back

First I start with the 3D modeling, I selected the Fusion 360 software to design it completely

Fusion 360

Fusion 360 is a cloud-based 3D CAD, CAM, and CAE software by Autodesk. It integrates design, simulation, electronics, and manufacturing tools into a single platform. Users can create solid models, assemblies, and detailed drawings with parametric and freeform modeling. It supports FEA and CFD simulations for mechanical validation. Fusion 360 enables CNC machining, 3D printing, and generative design. Its collaboration features allow real-time teamwork and version control.

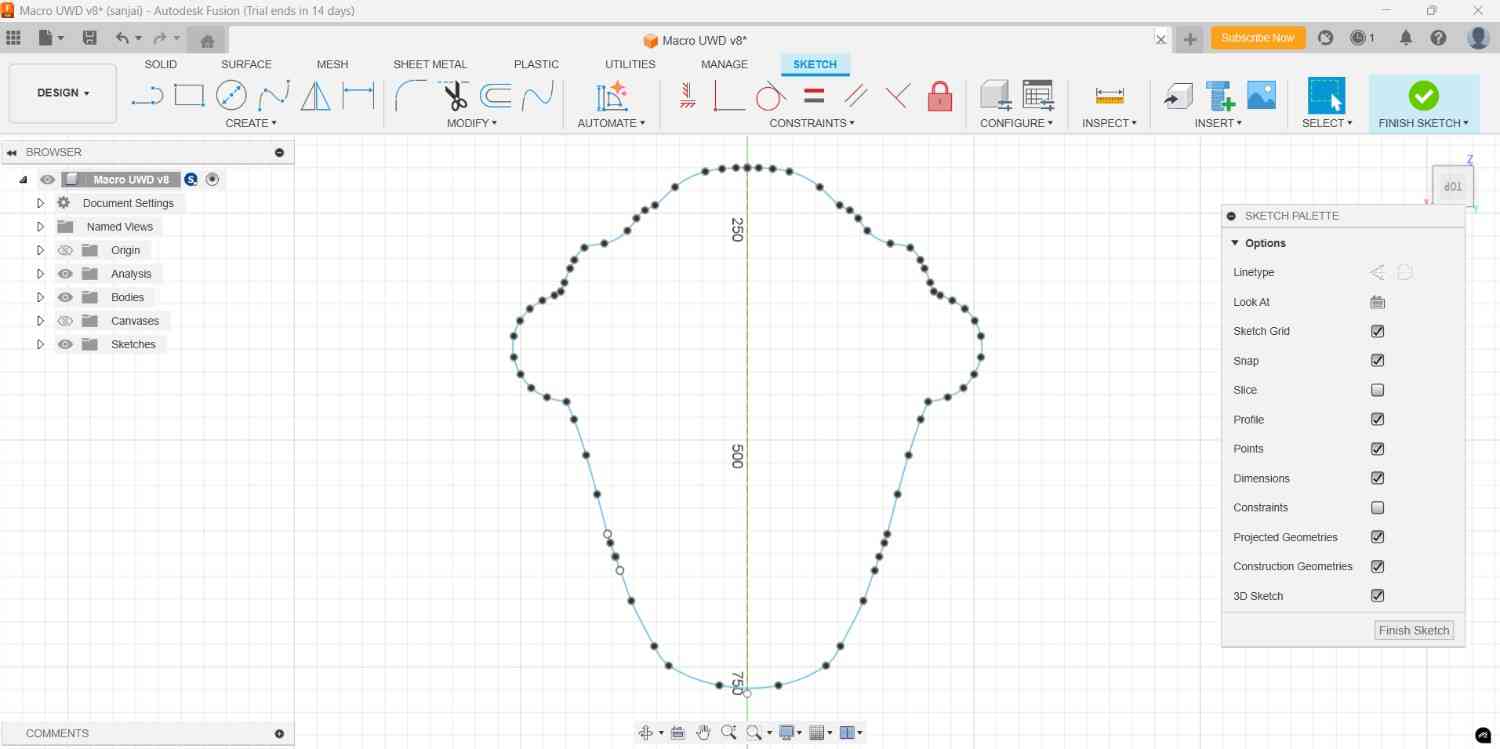

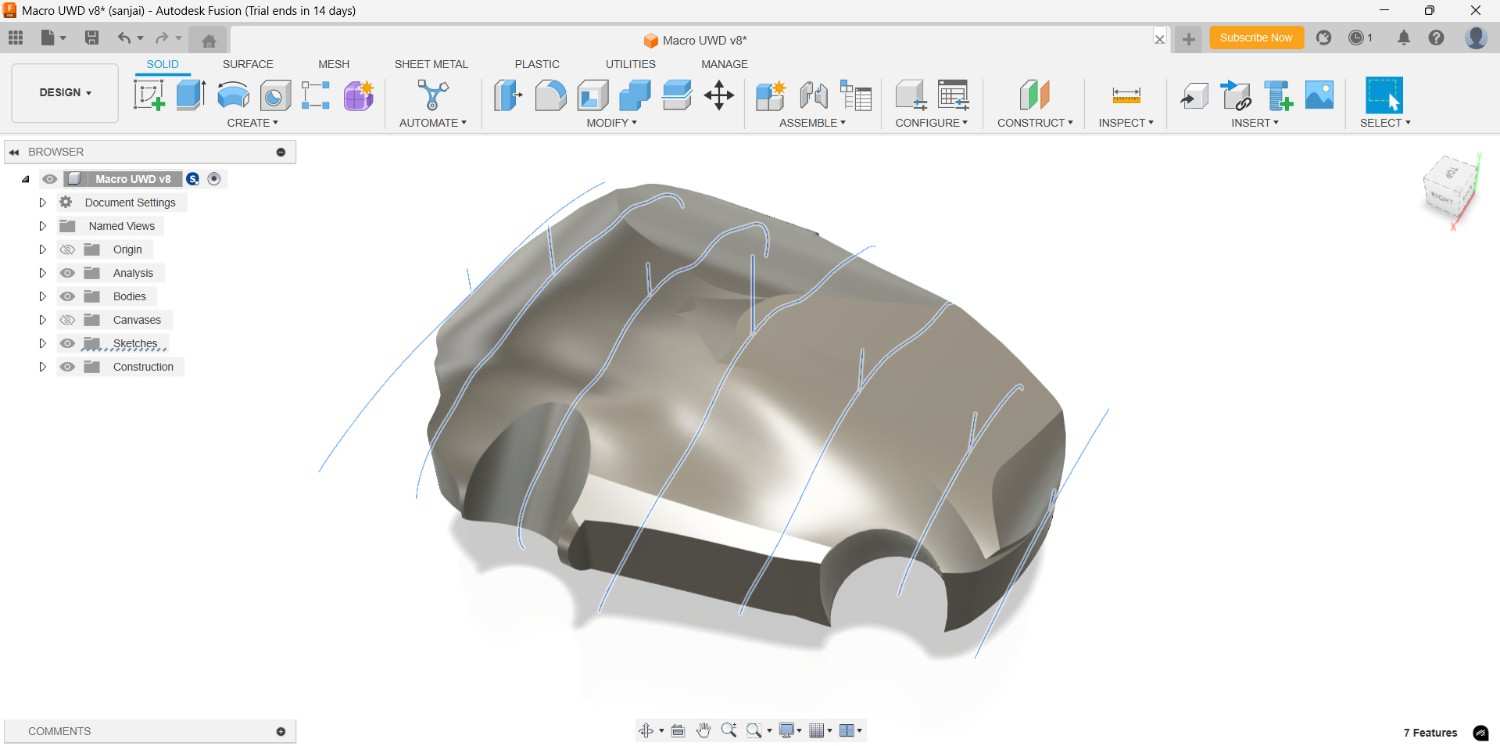

I planned my drone dimension approximately at first, then I start the rough sketch by using the spline obtion in Fusion sketch. I also took the one reference image from online to draw this.

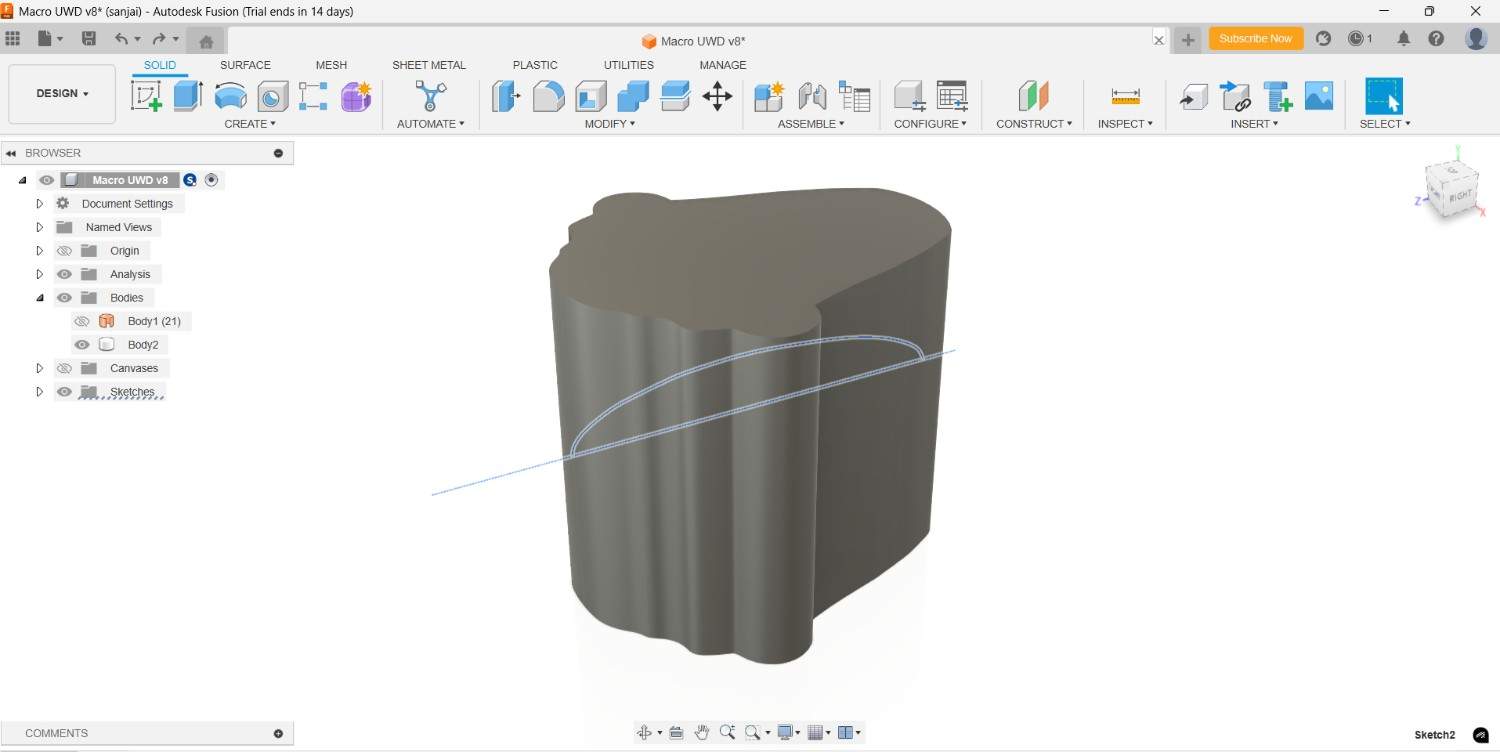

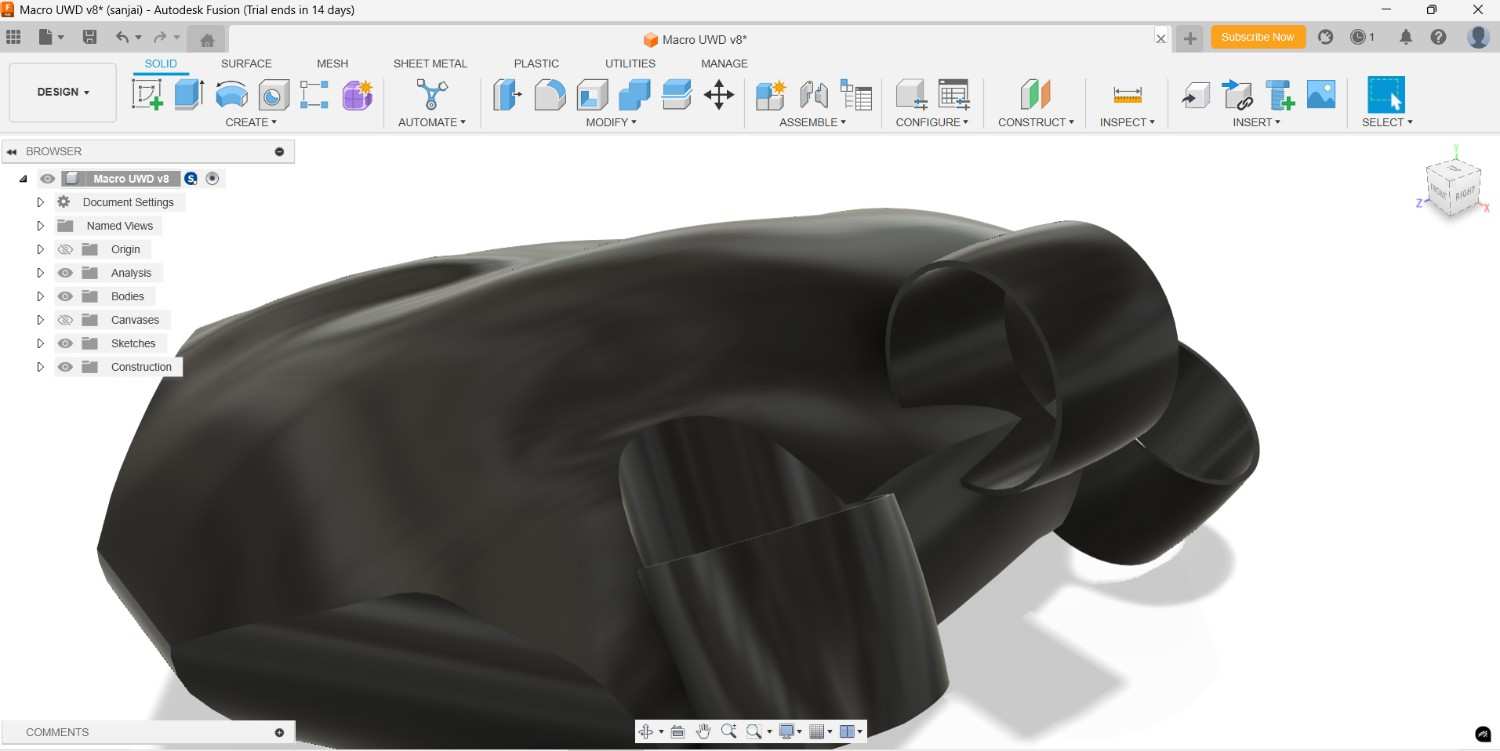

After I extrude it upto my required height with the help of Extruder command. Then i start the surface modeling method, I draw the spline and adjusting it with its lines

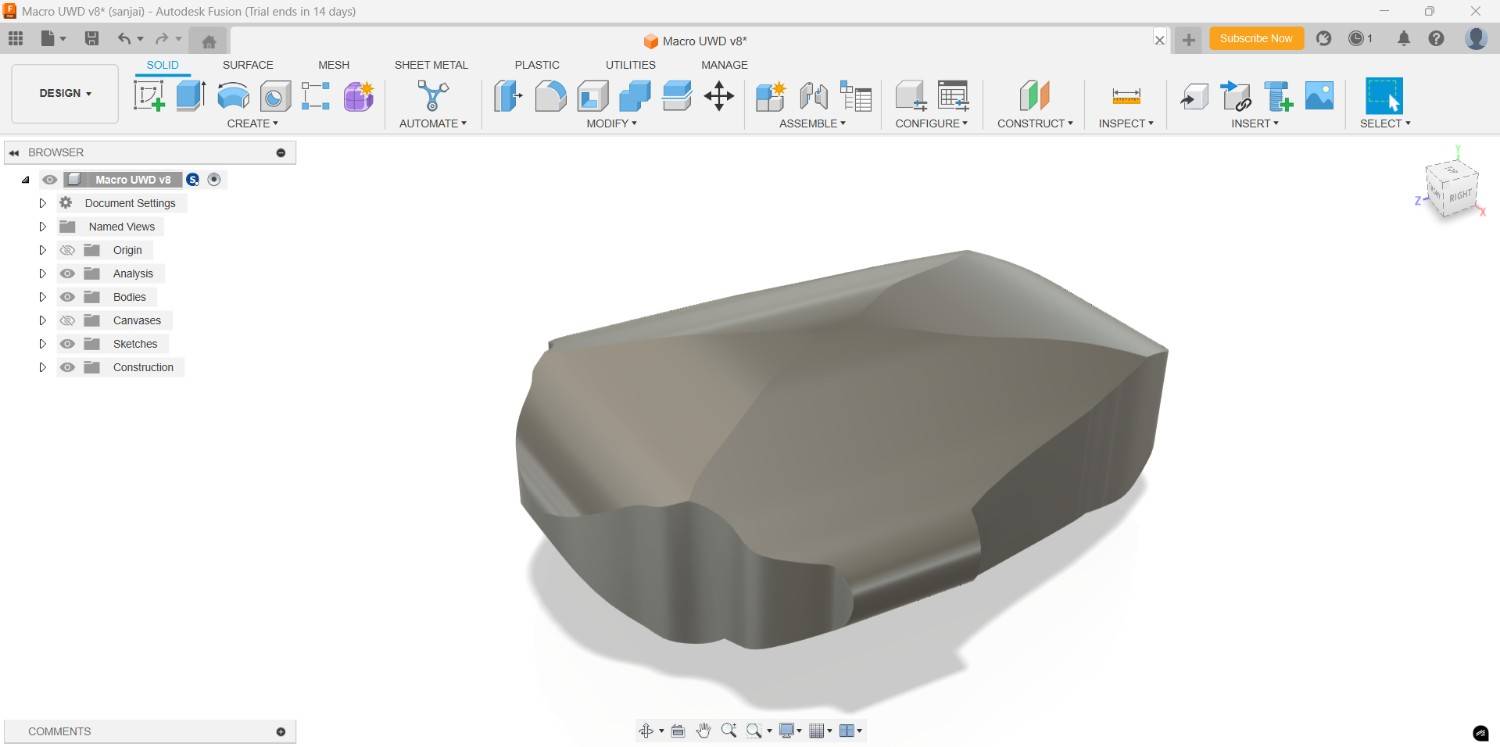

I cut the extra regions in the extruder part according to my perspective by using the split body command in side and front view

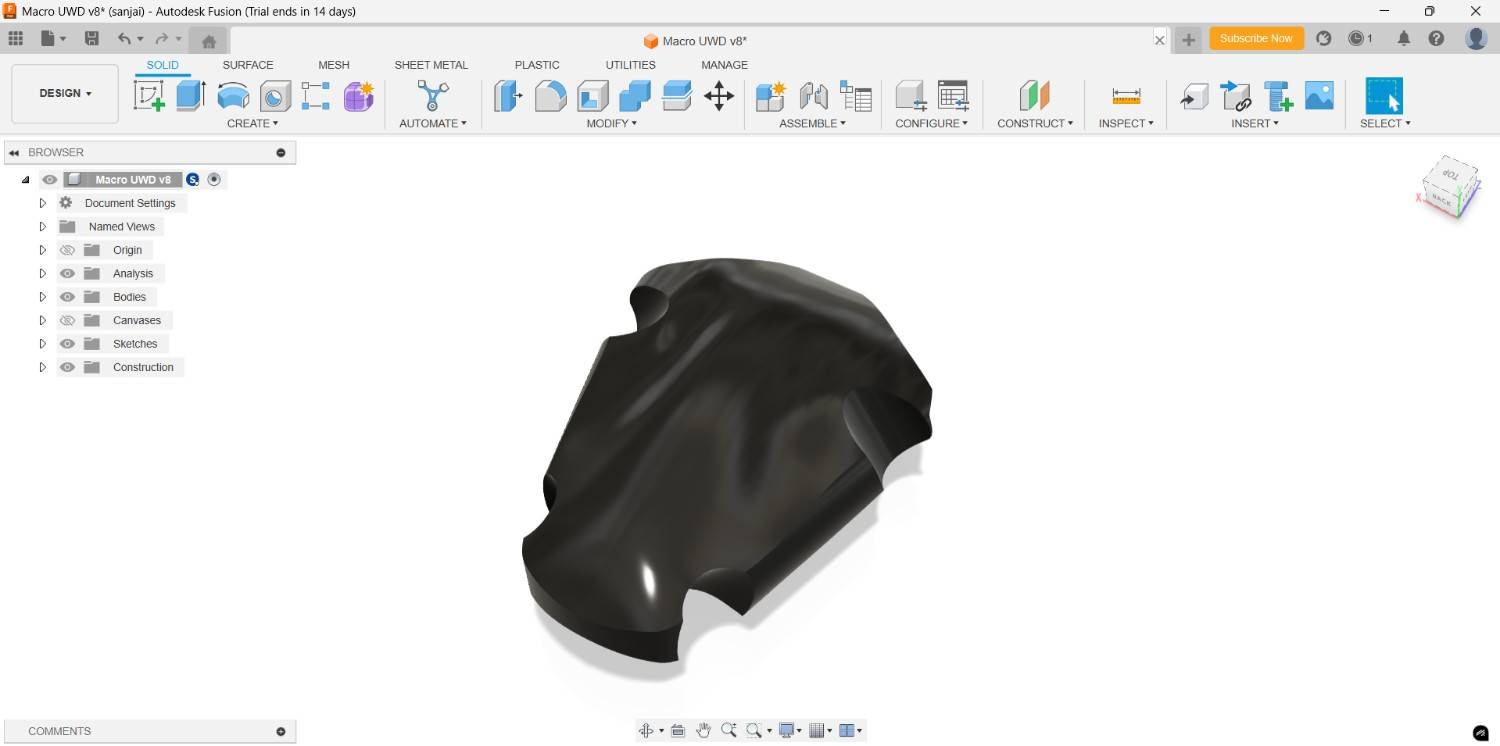

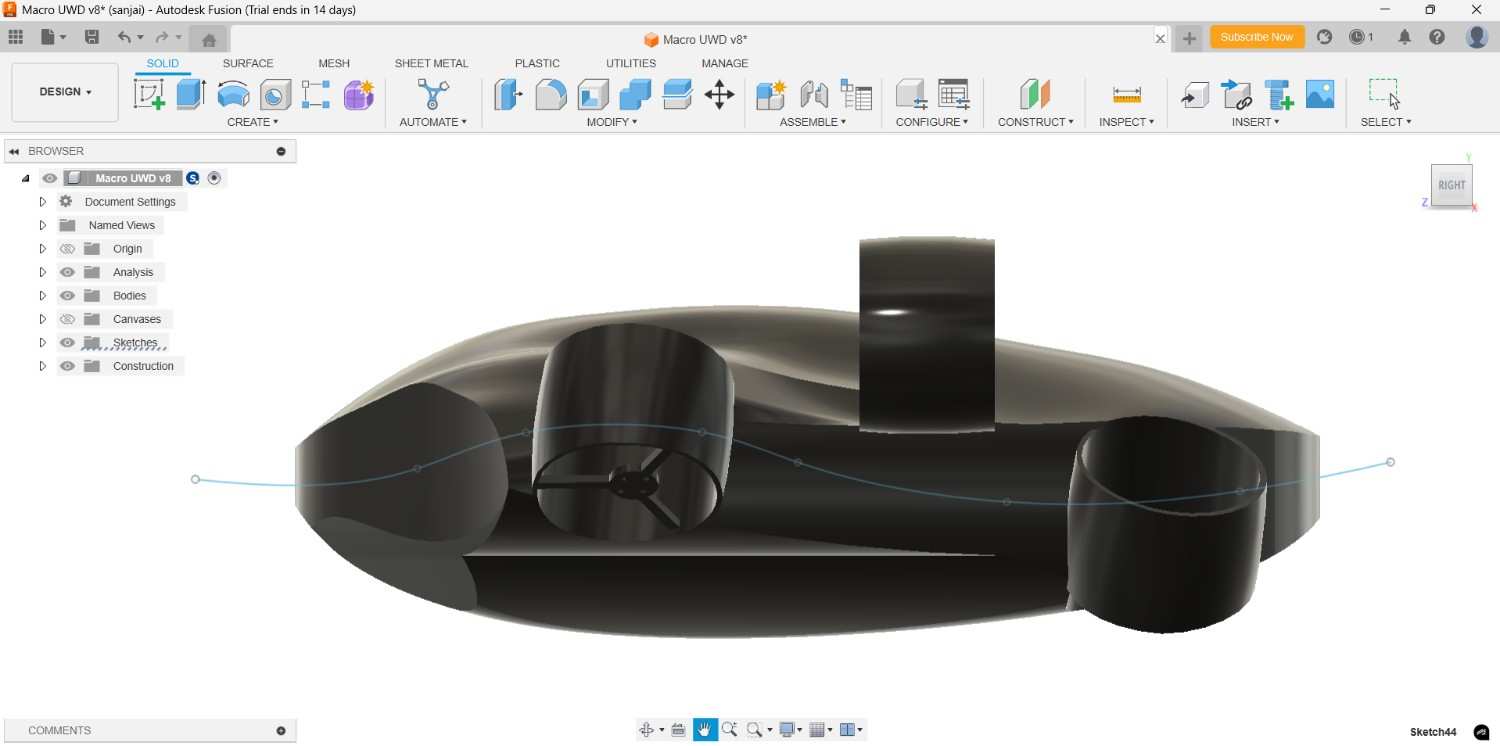

For the base design I did it properly, now I work on more with the detailed design. I create the one pillar respective to the drone drifting degree, then I place it into the determined position for the perfect orientation.

Then cut the body by using that angular body by using the combine tool, I select the main body as target body and the angular pillar as tool body and make the cut operation.

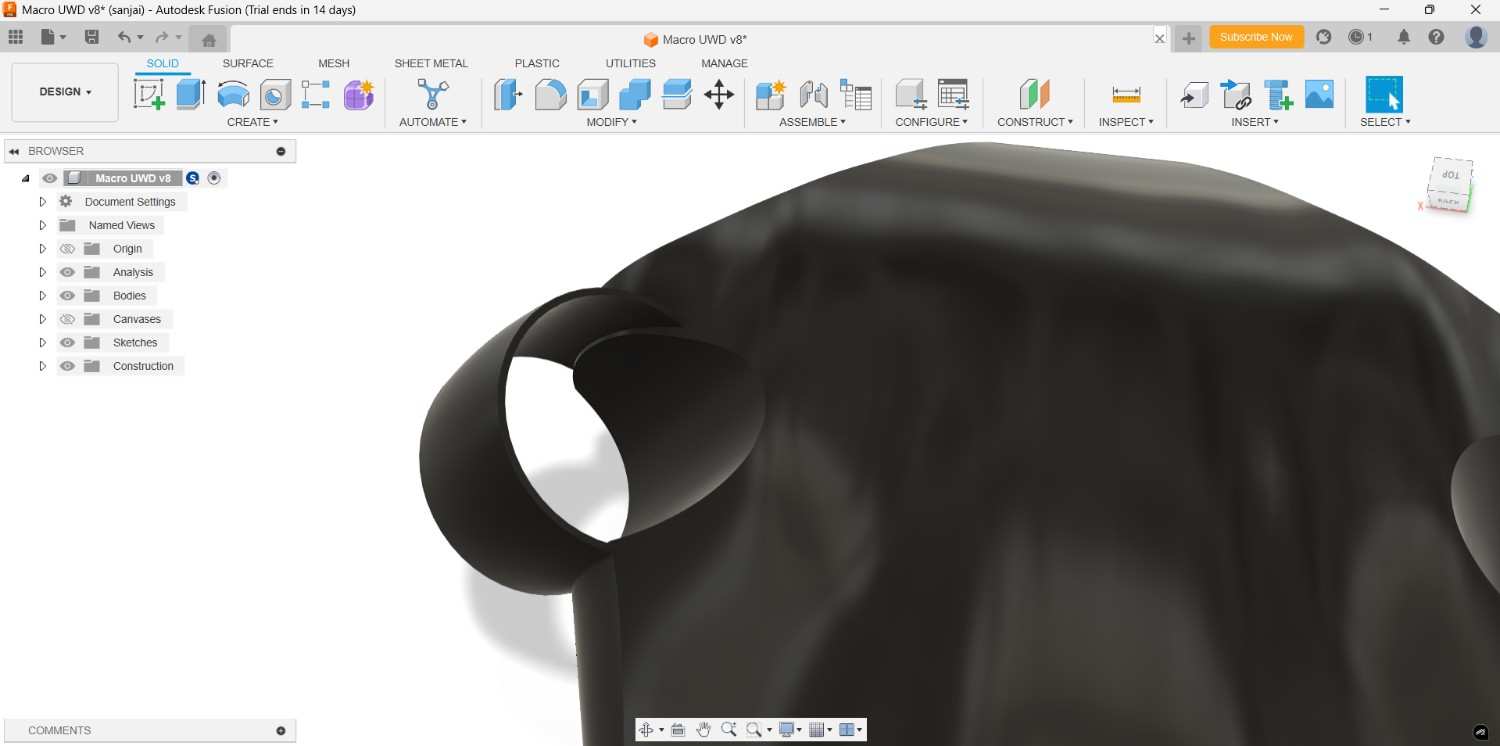

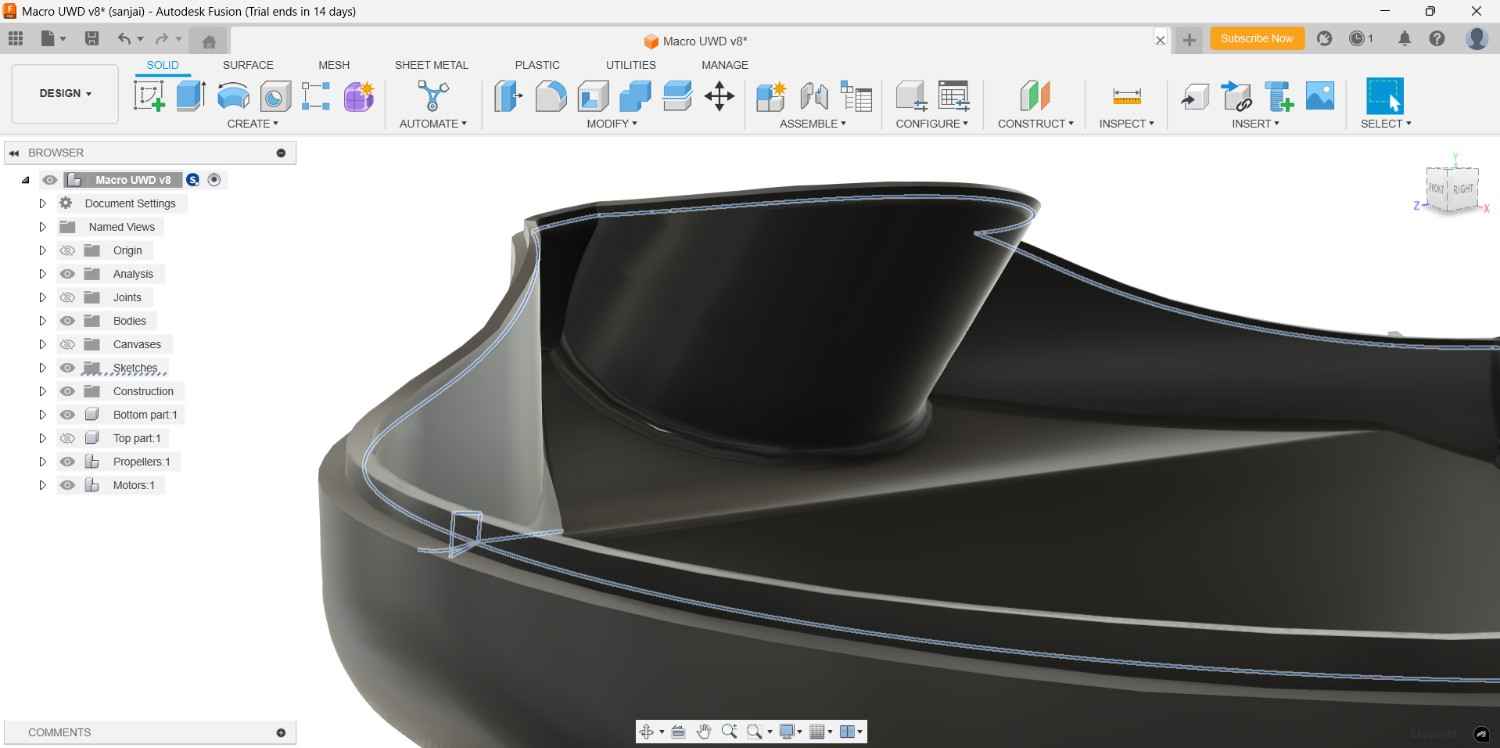

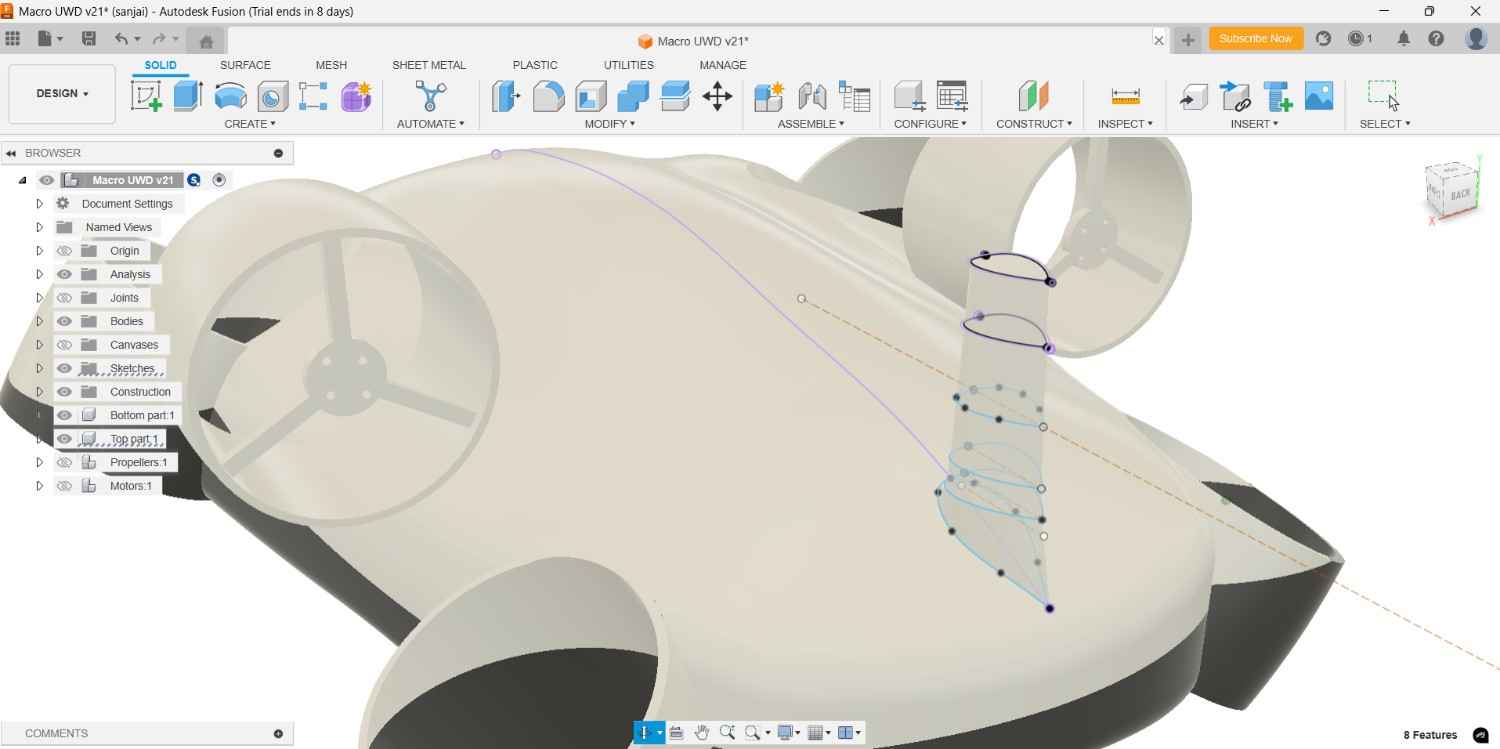

Then I go deep into the surface modeling, I create the offset plane with respective to my surface enhancement, draw the sketch by using the spline command.

After done the spline curved adjustment I did the cutting operation by took the spline as reference,

then cut the body in center by two, then recreate the body by using the mirror tool without changing the symmetry of either side.

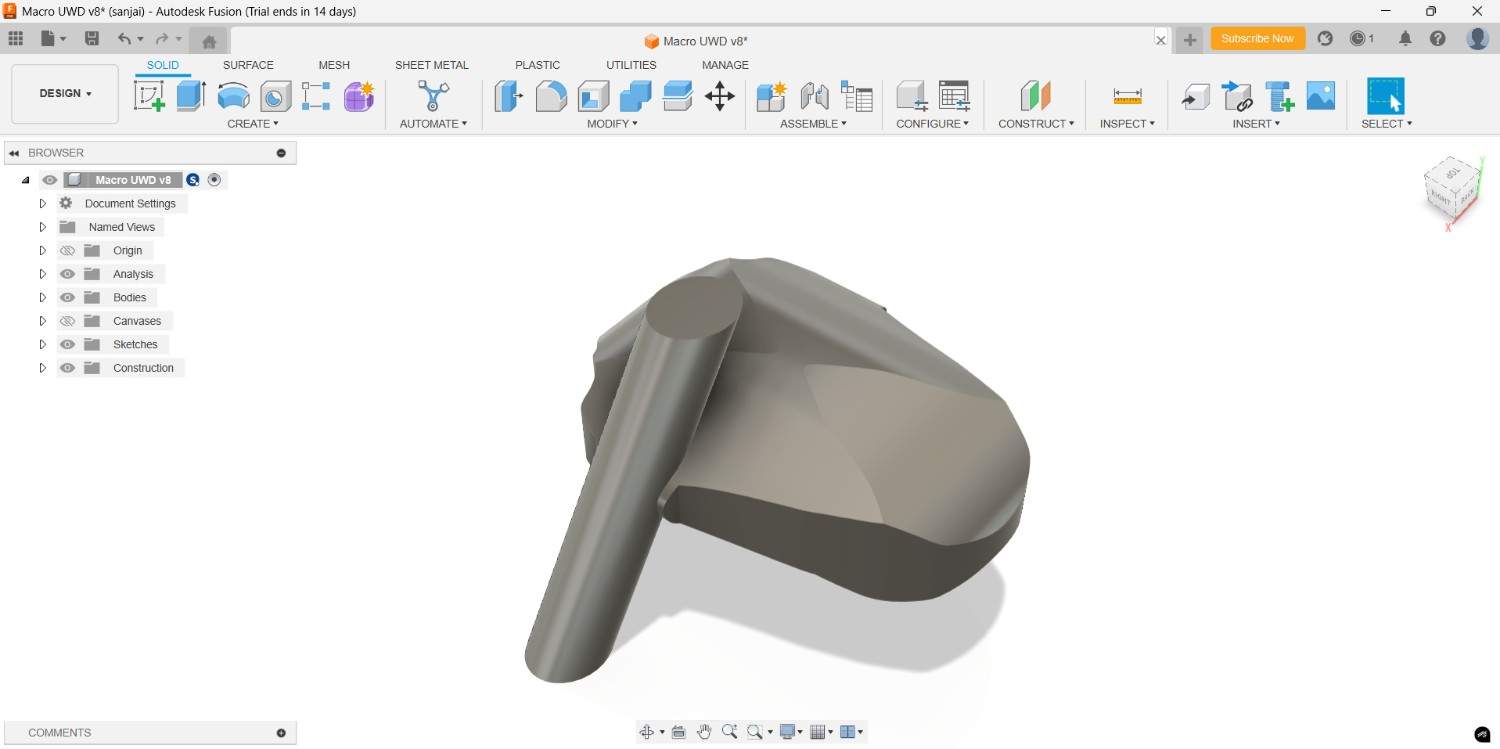

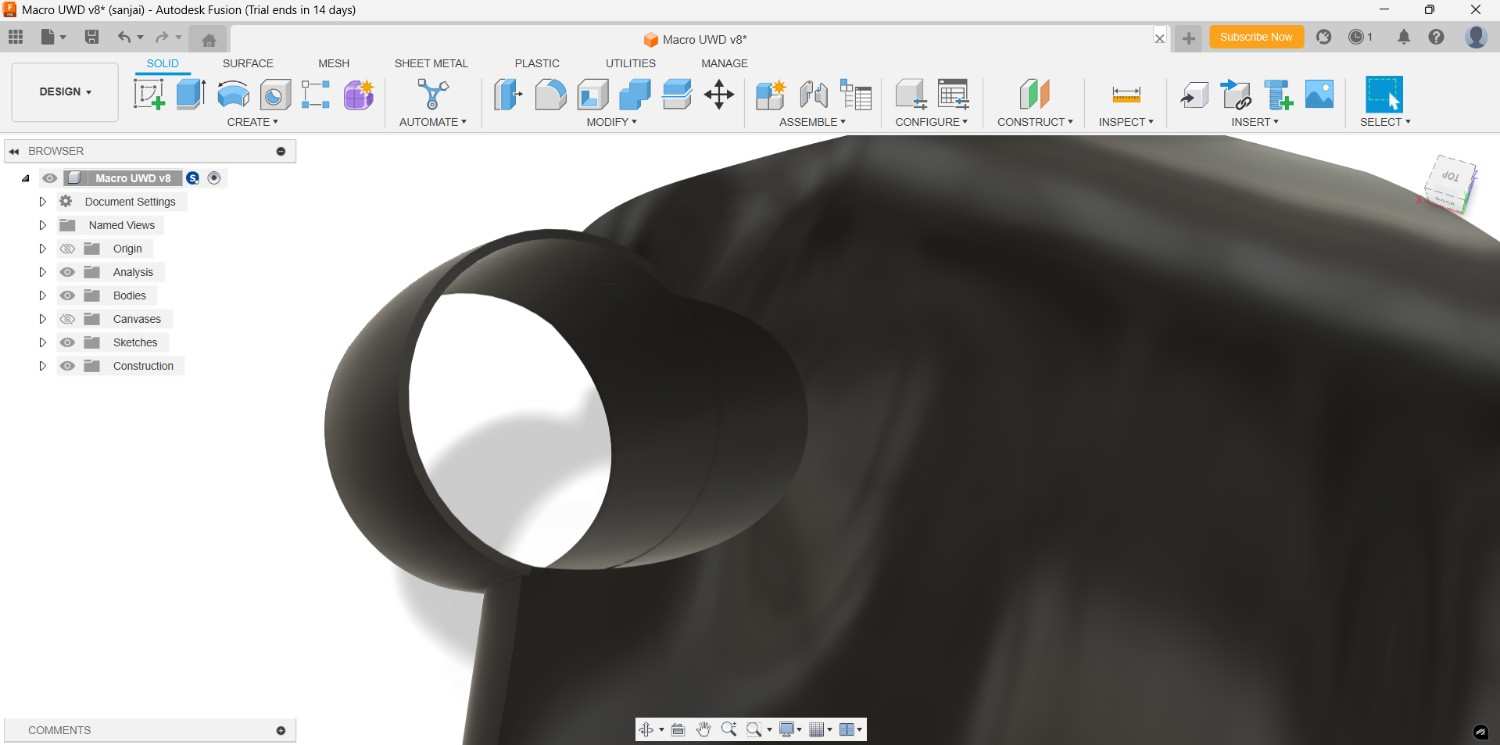

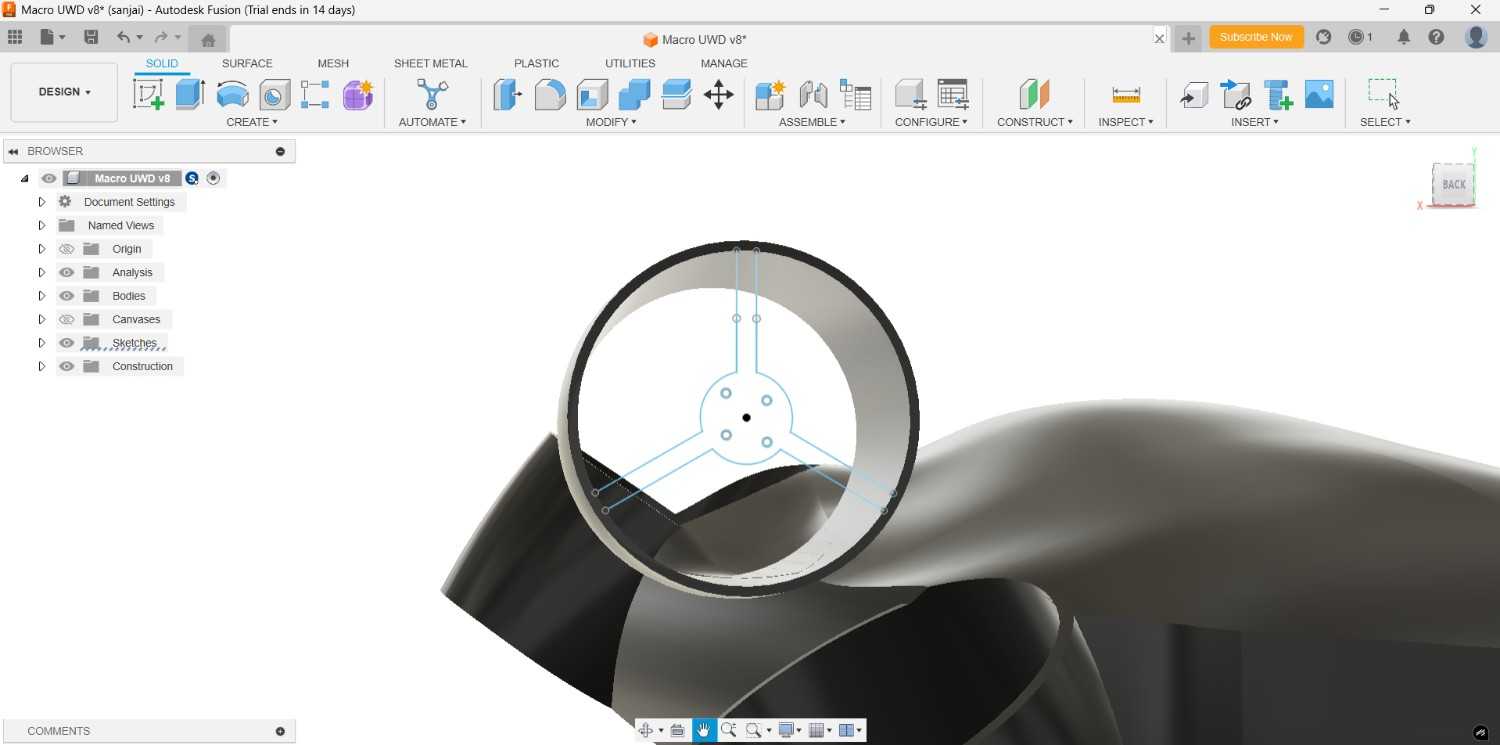

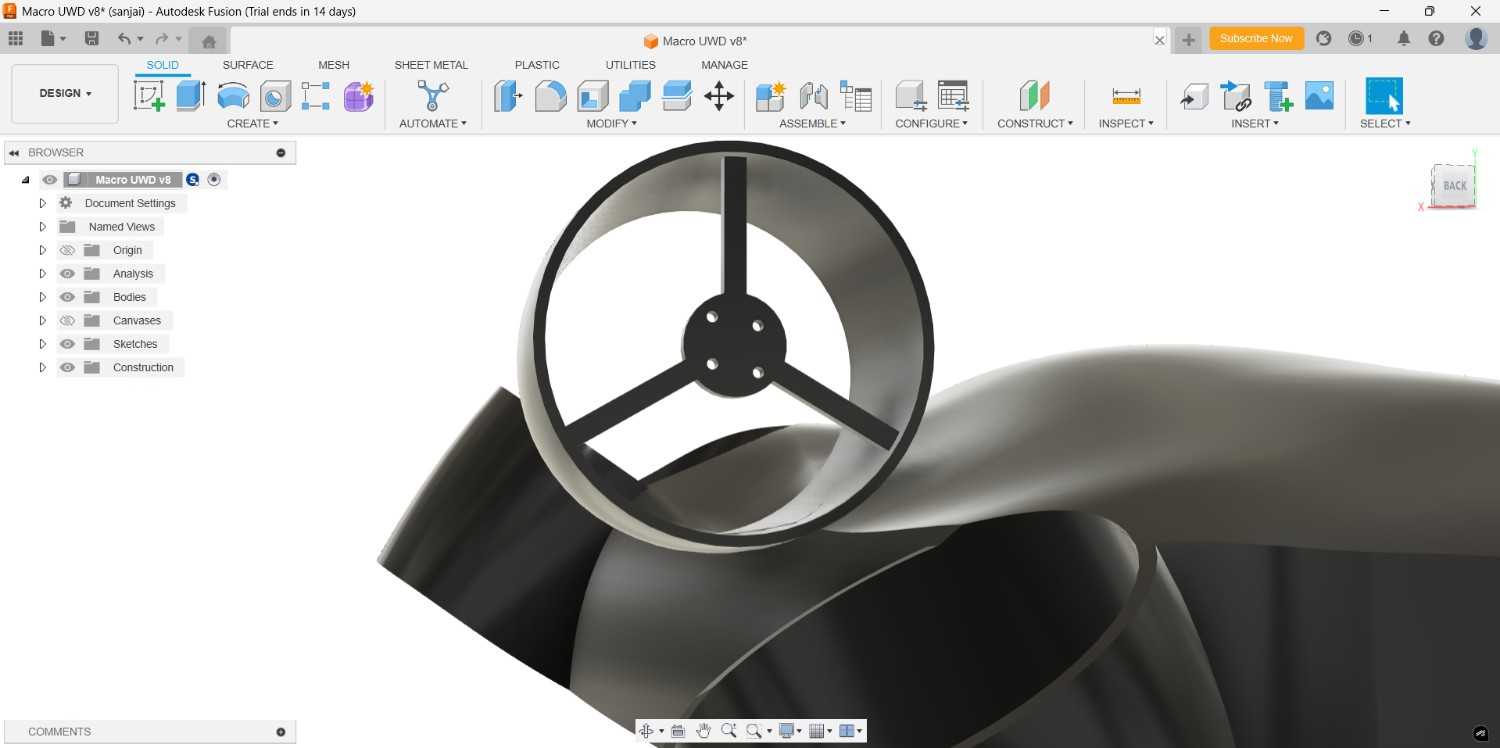

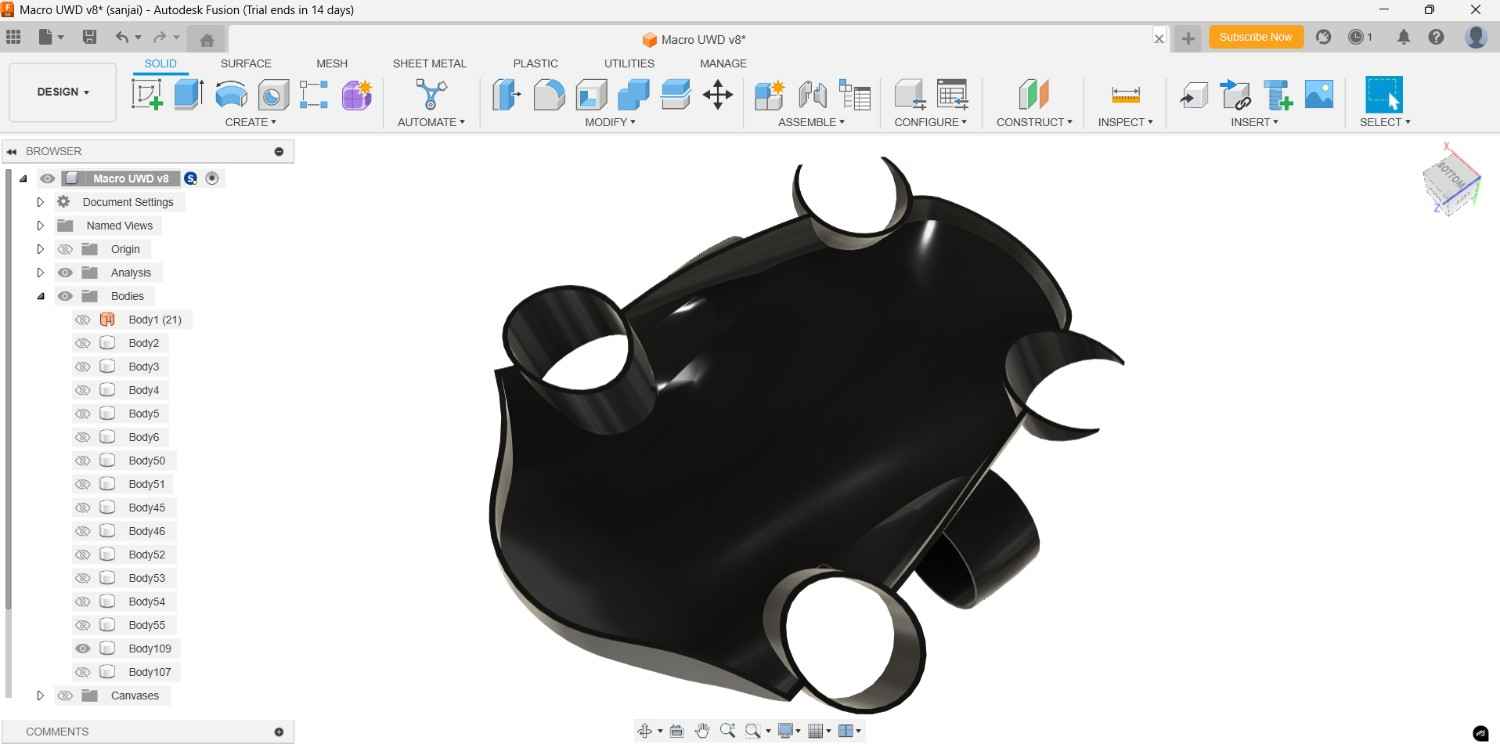

For the Motor and Propeller I draw the motor casing, I draw the line and use the arc command to close that, then adjust the position by dimension and revolve it by take one line as center.

At first I placed it the required position, but the it seems like some modification is needed to take the best output

Inner side of the casing the body came little bit so I use the split body command to rectify that.

Like that I am also do the same thing in back side and middle of the drone too

Then again I made some modifiaction for the proper design, then only it could be more dynamically function.

For the Motor and Propeller placement I created the base for the motor where we can fix the motor rigidly.

I made it for all the remaining casings also

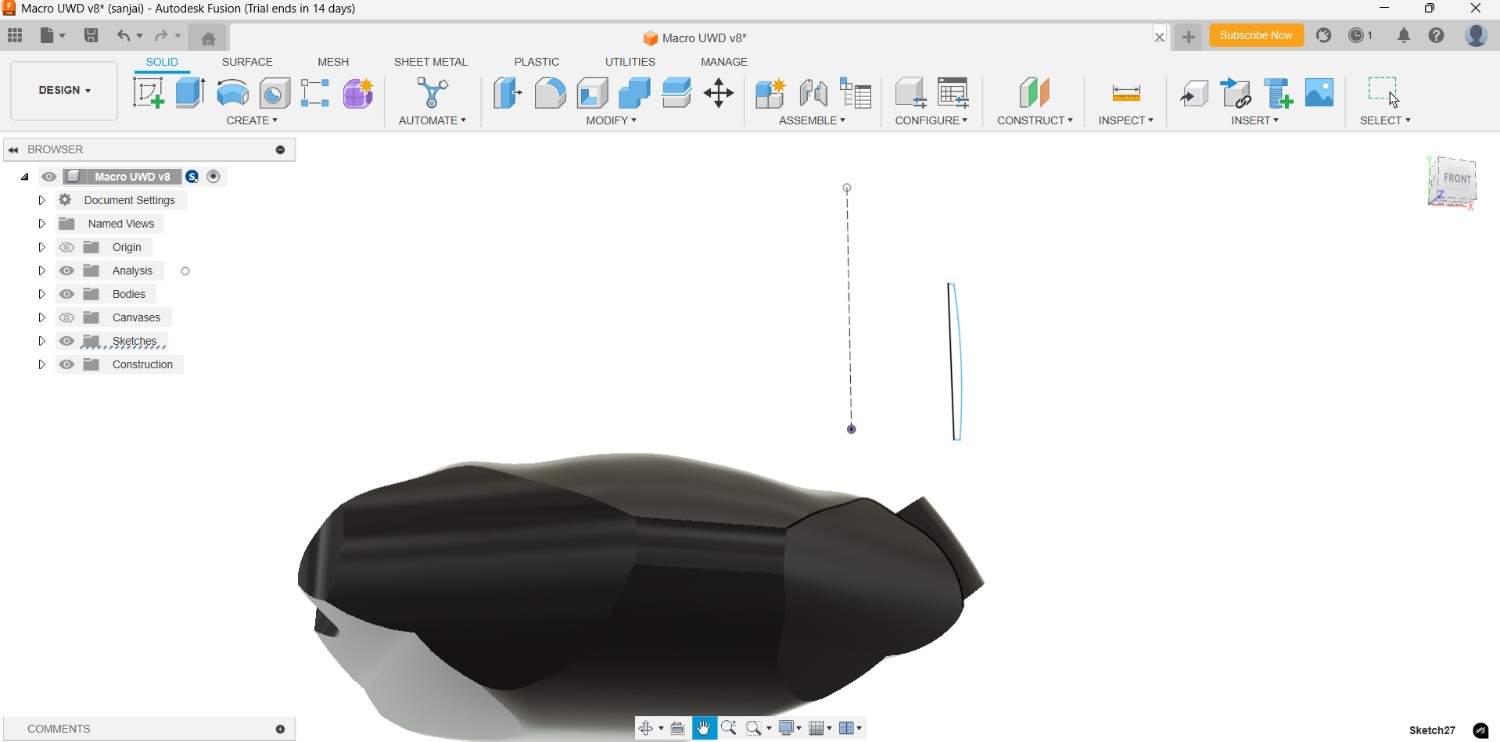

To place the Electronics inside we need the space in the drone inner part, so I drew the spline in one side and did split body by take the spline as cutting tool. Due to the Motor holder placement I drew the spline, because if I cut as straight line it will cut the holder as well, otherwise we can use the line as straight to cut out the body.

After the cutting operation the body only show as cutting block but we need the inner space, so use the shell command to obtain the required space, I gave the thickness 5 mm for rigid body, we can give upto 3 to 5 mm for the strong foundation of our design part.

Though it need to make as much as water proof design, so I draw the rectangle and extend across the body by using the sweep command.

After create it we also did the opposite thing in the other part. So I choose the combine command option, took the sweep done part as the tool body and which one is need to modified to took as target body and cut it out.

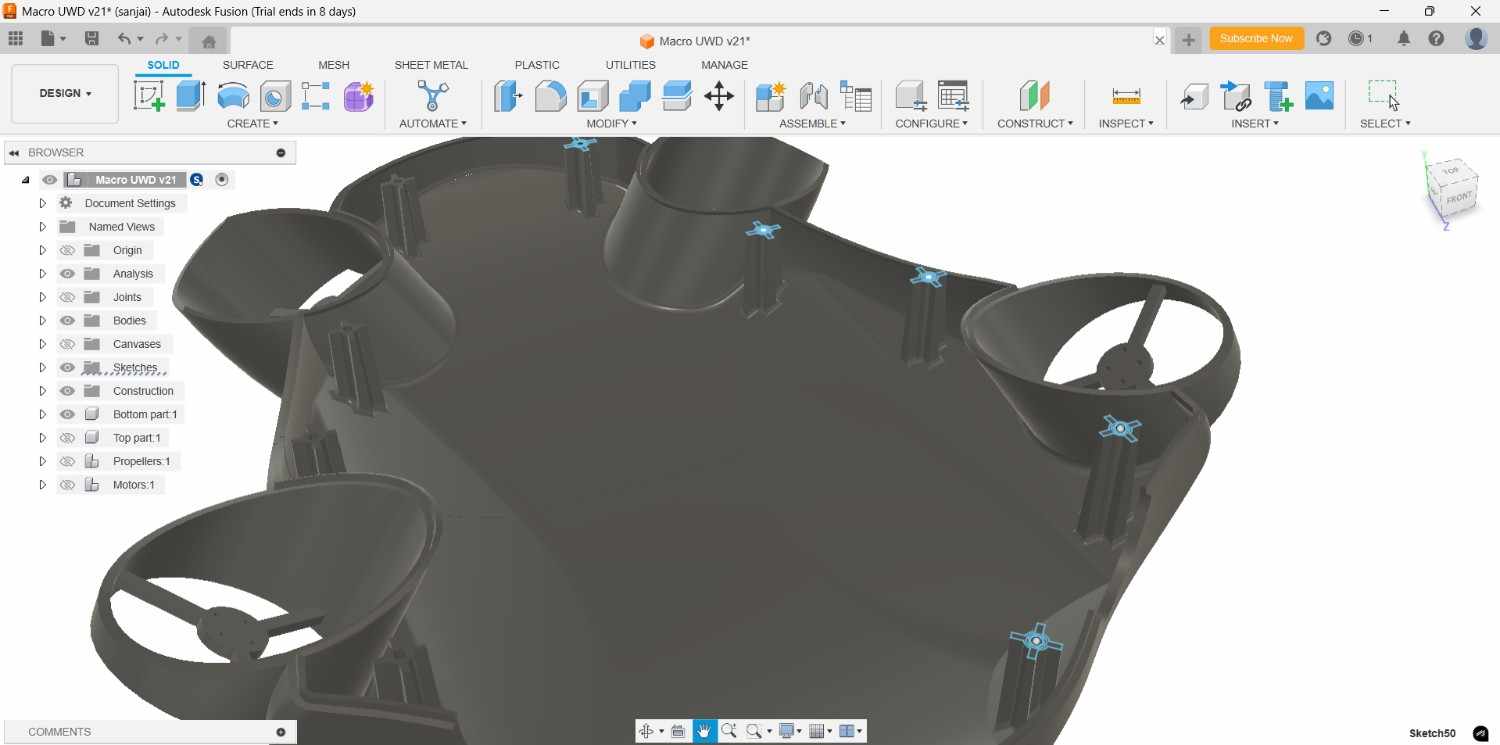

Then for the actual fitting I created the slots and extrude it both top and bottom parts with modifing some changes

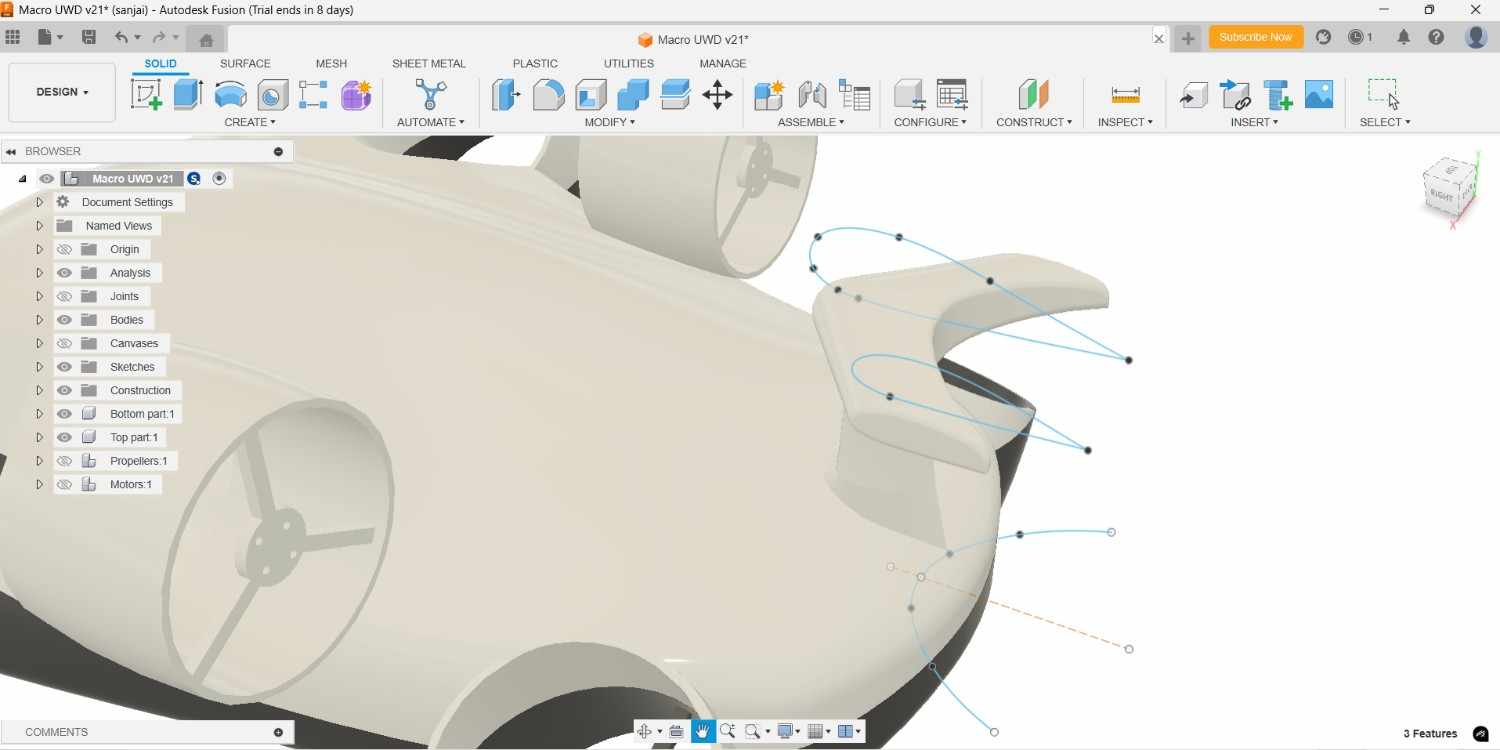

In back end of drone I planned to create the tail like component which is helpful for mitigate the wire risk when the drone is going to far without loosing by tide it completely.

For consider the Fluid dynamic I created it like smooth cure path then extend it by using the loft command.

In my case I planned to 3D print this parts with our Flash forge printer. Due to its volume capacity I should reduce the size to print it, so without scaling it I cut it out into 8 parts. Top part was cut into 4 parts, same as bottom parts cut into 4 parts, now I capable to do the 3D print in our Flash forge 3D printer.

For the lighting adjustment I create the hole infront of the drone